Design Modifications: At first, we were trying to make a gate system with all pneumatics, but because the whole class was trying to do that as well, it was extremely difficult to find enough parts for everyone. We discovered that we could get the same linear motion job done with motors, so we switched our whole project to this. An exception to the pneumatic requirement was made for our group because of this learning process we went through.

Final Design:

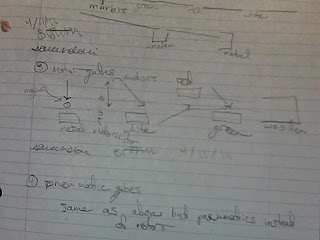

Our first picture is a where the marbles start-going over the magnet. This picks up the metal marbles and the adjacent gate pushes them into the basket. The marbles that aren't metal continue to roll into the gate, where the light and photoresistor examine them and give the reading to our program.Next, the program pushes out the right gate for the marble it has read and the gate that is holding the marble opens. The marble then slides right into the basket, guided by the just opened gate.

Lastly, the wooden marbles roll into a basket at the end, as the program does not open a gate for them.

This is a shot of our project as a whole. The red walls are used to guide the marbles from falling off the track.

Our programs are shown above and below. Above is the cascading sequence (a subprogram) that decides which gate to open after the photoresistor has done its reading. Below is the main program that refers to the subprogram, called "pushers".

- Reflection: We successfully a machine that differentiated between five types of marbles.

- Our model went through multiple prototypes.

- As explained earlier, there were not enough parts for us to use pneumatics, so we switched to motors. These turned out to be easier to program.

- A problem we ran into was that the color sensor we used was very sensitive and seemed to vary its readings from day to day. Before each use we had to test our values and adjust accordingly, but the design worked quite well after the adjustments.

- Our other dilemma was getting it below 2 minutes. The machine we designed sorted 15 marbles in approximately 2 minutes and 25 seconds. We were given an exception for this, because motors work slower than pneumatics.

- Regarding our programming, we made a main program with a singular subprogram imbedded in it, as mentioned above. It was a challenge to program because neither of us had ever made such an intricate program before but we received help from both David Cuban and Austin VonPohle and were able to make a working program. Overall, we believe that we succeeded in making a working program with a efficient machine.